PROCESS

In the meeting of architecture and light, RSL always tackles all tasks, large and small, functional and emotional, with the analytical eye and authority derived from design and production-engineering expertise. Each product not only represents »Made in Germany« workmanship, but »Made in Sankt Augustin« workmanship, as all of the components needed for custom luminaire manufacture are produced by machine and hand at the company’s own production facilities. This allows the creative source to be sure of smooth communication and the greatest possible level of flexibility in the often short timeframes of construction projects.

1. IDEA

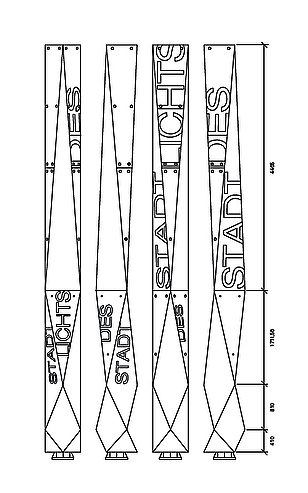

Suitable luminaires for challenging illumination tasks in high-grade architecture are often not available as standard. Therefore, planners and architects devise the right luminaire for their project from scratch to ensure the best possible outcome. The ideas are usually just sketches on paper, with all of the technical and construction details left to RSL.

The ideas of the creative partners from professional light planning/lighting design range from subtle interior luminaires combining different lighting technology functions in one and decorative, opulent iconic luminaires to extravagant light sculptures or huge pole luminaires for external areas. The ideas for these may be based on pure necessity or creative urges. The results may be technically or emotionally based, small or large, one-off pieces or limited series. However, one thing never changes – they are as individual as the people who devise them.

2. COMMUNICATION

The ability to listen is a high art. Simply having the will to listen is not enough; the skill must also be constantly practiced. For a manufacturer of custom luminaires based on the sketched ideas of external creative partners, listening is a basic prerequisite to a successful design and construction process. It is precisely when an idea is so unconventional that its implementation seems impossible at first glance that concentrated intellectual comprehension, free of reservations and objections, is the guarantee for an exceptional result. After all, it is generally known that energy follows attention. At RSL, listening is a given and part of its professionalism.

RSL is an active contributor in this second step, as this is where the expertise and experience in technology and design come in. The fundamental implementation possibilities are presented and initial detailed solutions discussed. This can lead to strong debate at times if the idea and realisation potential do not match completely and a common denominator must be found. However, the end result is always detailed solutions which fulfil the aesthetic standards of all involved while staying within the given budget.

3. CONSTRUCTION

Action follows closely on the heels of listening and discussion. Using the sketched draft and verbally communicated information, RSL specialists take care of the technical and construction aspects of the product development. There is often more than one possible solution. Considerations start with the interaction of the components, continue via the thermal requirements and end with competitive pricing. What makes RSL stand out in this is its focus on the best result, rather than the fastest. The electrics, thermal properties and light technology of the output are first tested in the company’s own laboratories. It is then condensed by the experts into a precisely detailed construction principle in the form of technical drawings, 3D representations and sometimes even a prototype. Given the intensive, professional preparation stage, there is then usually nothing standing in the way of production approval.

4. PRODUCTION

Supported by high-end technology, a value-added process with unrivalled quality, reliable functioning and the uniqueness of the product result from the RSL corporate philosophy of always doing one’s best and reinventing oneself.

All components needed to construct the custom luminaires are manufactured in-house. The company has ultra-modern CNC equipment, laser and bending machines, metal processing facilities, a computer-operated colour mixing system and powder coating and wet painting booths on its premises in Sankt Augustin for this purpose. This production integration is the ultimate guarantee of unparalleled product quality. It is a must given the flexibility required of manufacturers of professional custom luminaires. After all, a building project may necessitate modifications during the production process. It can often be the case that the actual installation point does not match the plans. Then the product‘s dimensions must be quickly changed, without impacting on the light quality. Thanks to the technical equipment and expertise of its employees, RSL is able to react on an ad hoc and solution-oriented basis in such situations.

5. LOGISTIC

Great organisational skills are needed to get the finished product to its destination when dealing with large luminaires. In such cases, the client can be sure of getting the right advice from RSL. Indeed, the company can even handle the entire delivery to the place of installation. This service for custom luminaires of excess dimensions is not only available within Germany, of course, but also internationally.

RSL also offers an assembly service. Giving almost personified assembly instruction, on-site RSL employees explain the construction principle, individual assembly steps and special requirements needed for safe, stable assembly. At this point, at the end of the value-added chain, the project managers, planners and clients can be sure of everything being in its right place.